In busy manufacturing plants, distribution centers, and healthcare facilities, excessive noise isn’t just irritating it can impact safety, communication, and productivity. Quiet and Noise Reducing Casters are designed to tackle this problem head-on, delivering smooth, low-noise mobility for everything from light carts to heavy-duty industrial equipment.

This guide will walk you through how these casters work, where they shine, and what to look for when choosing the best solution for your needs. Along the way, we’ll also provide a professional overview of leading manufacturers and product categories so you can make an informed purchase decision.

What Are Quiet and Noise Reducing Casters?

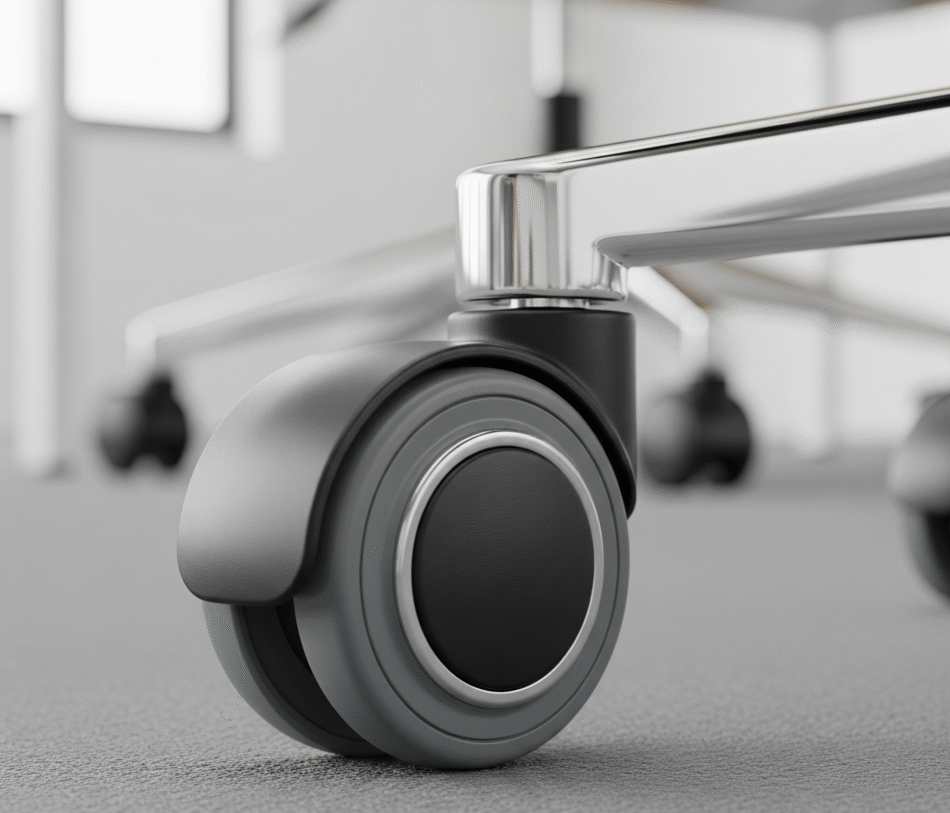

Quiet and noise reducing casters are specialized wheel assemblies engineered to minimize vibration and reduce the sound generated when equipment moves across floors. They typically use softer tread materials, advanced bearing systems, and shock-absorbing designs to reduce decibels without sacrificing performance.

These casters can be found in:

- Hospitals and labs – to maintain quiet, sterile environments.

- Warehouses and factories – to reduce noise pollution and protect worker hearing.

- Office and retail spaces – for smooth, unobtrusive movement of equipment.

Why Noise Reduction Matters in Industrial Environments

Noise in the workplace isn’t just a nuisance it’s a health hazard. According to OSHA, prolonged exposure to high noise levels can lead to permanent hearing loss and increased workplace accidents due to miscommunication.

Low-noise casters not only protect workers but also:

- Improve productivity by reducing distractions.

- Enhance customer experience in commercial environments.

- Meet compliance with noise regulations in certain industries.

Key Benefits of Quiet and Noise Reducing Casters

- Reduced Decibel Levels – Less noise when rolling over concrete, tile, or uneven surfaces.

- Enhanced Safety – Easier communication between staff in busy environments.

- Floor Protection – Softer tread materials prevent scratches and scuffs.

- Heavy Duty Options Available – Models like noise reducing heavy duty industrial casters handle large loads quietly.

Product Categories and Industrial Applications

When selecting a caster, consider the specific demands of your industry:

- Noise reducing industrial casters – Balanced for general industrial use.

- Quiet rolling casters – Ideal for carts, medical trolleys, and light equipment.

- Heavy duty noise reducing casters – Engineered for manufacturing, aerospace, and automotive facilities.

- Custom noise reducing casters – Designed to meet specialized load, size, or floor protection needs.

USA Made Caster Manufacturers

In the caster manufacturing industry, a few companies consistently stand out for innovation, build quality, and engineering excellence. Leading names like Casterconcepts, Aerol, Reaction Industries, and Conceptual Innovations have built strong reputations by delivering durable, high-performance solutions for demanding industrial applications.

These manufacturers are known for their ability to provide both standard and custom noise reducing casters, offering tailored designs that match the unique challenges of each facility from high-speed assembly lines to sensitive medical labs. Their expertise ensures that customers get more than just a caster; they get a mobility solution optimized for longevity, safety, and performance.

How to Choose the Right Quiet and Noise Reducing Casters

When selecting your casters, keep these considerations in mind:

- Load Capacity – Always match caster capacity to the heaviest expected load.

- Floor Type – Choose tread materials compatible with your flooring.

- Environment – Consider exposure to chemicals, temperature extremes, or moisture.

- Mobility Needs – Decide between swivel, rigid, or a combination for optimal maneuverability.

- Noise Level Requirements – Match caster technology to your target decibel range.

Maintenance Tips for Long-Lasting Performance

- Inspect wheels regularly for wear or debris.

- Lubricate bearings to maintain smooth rolling.

- Replace worn tread to maintain low noise levels.

- Tighten hardware to prevent rattling and vibration.

FAQ: Quiet and Noise Reducing Casters

- How do I make my existing casters quieter?

Upgrading to casters with softer treads or adding shock-absorbing mounts can significantly reduce noise. - Are quiet casters as durable as standard ones?

Yes, especially when you select noise reducing heavy duty industrial casters designed for high-load applications. - Can I get custom noise reducing casters?

Absolutely. Many leading manufacturers offer custom noise reducing casters for unique size, load, or environmental requirements.

Conclusion

The right Quiet and Noise Reducing Casters can transform your workplace protecting hearing, enhancing safety, and improving overall workflow. By understanding your operational needs and working with reputable manufacturers, you can invest in caster solutions that deliver both performance and peace of mind.