CNC machining stands for “Computer Numerical Control machining,” a process that uses computers to control machine tools. These tools can include mills, lathes, routers, and grinders. In CNC machining, designs are translated into instructions, which are then executed by the machine with precision. This process has revolutionized the manufacturing industry, allowing for greater accuracy, efficiency, and flexibility. The importance of CNC machining lies in its ability to produce high-quality parts in a variety of industries, from aerospace to automotive, and even in smaller scale operations like custom parts manufacturing.

The control of machine tools through computers makes CNC machining a versatile and automated process. By using a pre-programmed computer code, the machine performs a series of complex actions such as cutting, drilling, and milling without direct human intervention. This ensures that even the most intricate designs can be produced with high precision, reducing errors and increasing productivity. As a result, CNC machining has become a cornerstone of modern manufacturing.

The Evolution of CNC Machining

The concept of CNC machining is not new. The origins of CNC technology can be traced back to the 1940s when the first numerical control machines were developed. Early NC machines relied on punched tape to store instructions, which limited the complexity of the designs they could execute. However, the advent of digital computers in the 1960s led to the creation of CNC systems, which offered a far more advanced and efficient way of controlling machine tools. With the introduction of these systems, manufacturers were able to streamline their processes and make even more complicated parts with a higher degree of accuracy.

Today, What is CNC Machining has advanced even further with the integration of advanced software, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems. These systems work together to design and simulate machining operations before they are performed, reducing errors and material waste. Moreover, the introduction of 3D printing and additive manufacturing technologies has opened new frontiers for CNC machining, allowing industries to experiment with even more complex designs and materials.

How CNC Machining Works

CNC machining starts with the creation of a 3D digital model of the part to be manufactured. Engineers use CAD software to design the part, specifying all dimensions and materials. Once the design is finalized, it is converted into a machine-readable code known as G-code, which provides the instructions for the machine to follow. This G-code instructs the CNC machine on how to move its various components, such as the cutting tool or workpiece, to create the desired shape.

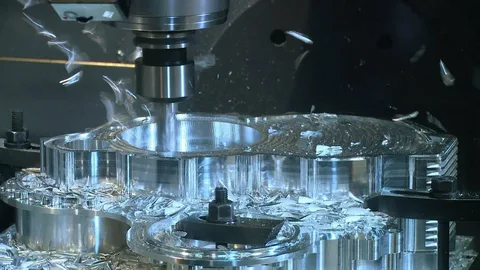

After the program is loaded into the CNC machine, the machine begins its work. The material is placed into the machine’s work area, where it is secured by clamps or fixtures. Depending on the type of CNC machine, different cutting tools are used to shape the material. The machine continuously monitors its position and makes adjustments in real-time to maintain the correct path as dictated by the G-code. As the process unfolds, layers of material are gradually removed, leaving the final part behind. CNC machines can create parts with high precision, whether they are simple geometric shapes or complex designs with intricate details.

Applications of CNC Machining in Various Industries

CNC machining has found applications across numerous industries, making it one of the most important technologies in modern manufacturing. In the aerospace industry, for example, CNC machines are used to create lightweight, durable parts that are critical for aircraft performance and safety. Components such as turbine blades, landing gear, and fuselage sections are often produced using CNC machining, ensuring tight tolerances and high-quality finishes.

In the automotive industry, CNC machining is used for both prototyping and mass production of car parts. Precision-machined components like engine blocks, transmission parts, and brake systems are made using CNC machines. The ability to produce parts with such precision allows for better performance and reliability of vehicles. CNC machining is also used in industries such as medical device manufacturing, electronics, and energy production. The versatility of CNC machines makes them suitable for a wide range of applications, ensuring their continued relevance in industrial production.

The Benefits of CNC Machining

One of the main advantages of CNC machining is its precision. CNC machines are capable of producing parts with extremely tight tolerances, often within fractions of a millimeter. This level of accuracy is difficult to achieve with manual machining, where human error can play a significant role. The precision of CNC machining ensures that parts fit together perfectly, leading to fewer defects and rework in the production process.

CNC machining also offers significant improvements in efficiency and productivity. Since the machines are automated, they can operate continuously without the need for breaks or downtime, maximizing output. Additionally, CNC machining is capable of producing complex designs with minimal human intervention, reducing the labor costs associated with manual machining. Furthermore, CNC machines can work with a wide variety of materials, including metals, plastics, and composites, giving manufacturers the flexibility to create parts suited to their specific needs. Overall, CNC machining represents a significant step forward in manufacturing, providing industries with an efficient and reliable means of producing high-quality parts.

The Future of CNC Machining

The future of CNC machining looks promising, with continual advancements in technology paving the way for even more precise and efficient manufacturing processes. The integration of artificial intelligence (AI) and machine learning into CNC systems is one of the most exciting developments. These technologies can enable CNC machines to make real-time decisions, adjust to changing conditions, and optimize production processes without human intervention. This will lead to even greater levels of automation, reducing the need for manual input and further increasing productivity.

Additionally, the ongoing improvement of materials and coatings used in CNC machining will further enhance its capabilities. New materials with enhanced strength, durability, and resistance to wear and corrosion will allow CNC machines to produce even more complex parts that can withstand harsh environments. As additive manufacturing technologies continue to improve, it is likely that CNC machining will evolve to incorporate 3D printing capabilities, expanding the possibilities for part design and material usage. These advancements will help industries stay competitive by enabling them to produce high-quality, cost-effective products in shorter timeframes.

Conclusion

In conclusion, CNC machining is an essential process in modern manufacturing, offering numerous advantages over traditional methods. From its ability to produce highly precise parts to its efficiency and flexibility in working with a variety of materials, CNC machining is an indispensable tool in industries ranging from aerospace to automotive and medical device manufacturing. As technology continues to advance, CNC machining will only become more important, paving the way for the creation of even more complex and durable parts with greater efficiency.

The role of CNC machining in the industry cannot be overstated. It allows manufacturers to produce high-quality, custom-made products with exceptional accuracy and speed, making it a vital technology in the competitive global marketplace. As industries continue to demand faster production times and more innovative designs, CNC machining will remain at the forefront of manufacturing technology, driving progress and shaping the future of industrial production.