Rotary lobe pumps have long been the go-to solution for a wide range of industries that require efficient fluid transfer. Whether you’re in the food processing, chemical, pharmaceutical, or wastewater management industries, these pumps are essential for maintaining smooth and continuous operations. Ace Lobe Pumps, a trusted name in the industry, has been at the forefront of producing high-quality rotary lobe pumps that ensure optimal performance for various applications.

In this article, we will dive deep into what rotary lobe pumps are, how they work, their advantages, and why choosing the right rotary lobe pump is crucial for your business operations.

What is a Rotary Lobe Pump?

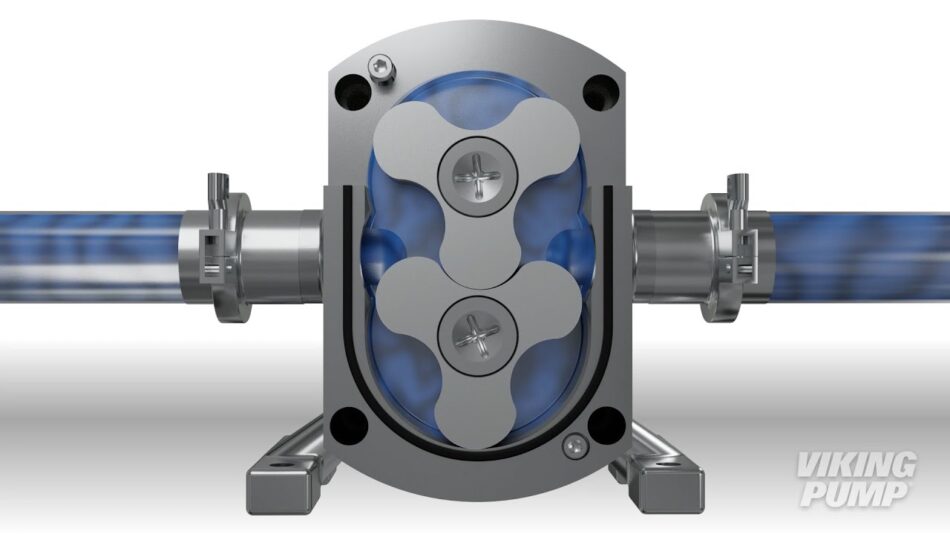

A rotary lobe pump is a type of positive displacement pump, designed to move liquids through a system using two or more lobes that rotate in a specific manner. These pumps are unique because of their simple yet highly efficient design, which is capable of transferring thick, viscous fluids with ease.

Unlike centrifugal pumps, which rely on speed to move liquids, rotary lobe pumps use the mechanical movement of the rotating lobes to create suction, making them suitable for thicker liquids like slurries, pastes, and even gases.

The Anatomy of a Rotary Lobe Pump

A typical rotary lobe pump consists of the following main components:

- Rotary Lobes: These are the heart of the pump, where the actual displacement of fluids occurs. The lobes rotate in a fixed cavity, pulling liquid into the pump chamber and pushing it out.

- Pump Casing: This houses the lobes and ensures that fluid is transferred without leakage. It is often designed with materials resistant to corrosion or abrasion.

- Shafts: These connect to the lobes, enabling their rotation. The shafts are powered by an electric motor or engine.

- Inlet and Outlet Ports: These are the entry and exit points for the fluid. The inlet allows liquid to be drawn into the pump, while the outlet pushes it out.

- Seals and Bearings: These components maintain the integrity of the pump, ensuring that no fluid escapes from the casing and that the lobes rotate smoothly.

How Do Rotary Lobe Pumps Work?

The operation of a rotary lobe pump is based on a simple principle. As the lobes rotate, they create an expanding cavity that draws fluid into the pump. Once the cavity reaches its maximum size, the fluid is trapped and pushed through the system as the lobes continue to rotate, reducing the cavity size and expelling the fluid.

This unique method of fluid movement ensures that rotary lobe pumps deliver a steady flow, making them ideal for industries where consistency is key. The pumps are highly adaptable and can be designed with different configurations of lobes, materials, and pump sizes to suit specific requirements.

Key Benefits of Rotary Lobe Pumps

There are several advantages to choosing rotary lobe pumps, which makes them a popular choice across multiple industries. Let’s look at some of the most prominent benefits:

- Versatility: These pumps can handle a wide variety of liquids, from water-like fluids to thick sludges. Their adaptability makes them indispensable in diverse applications.

- High Efficiency: Because they are positive displacement pumps, rotary lobe pumps are highly efficient, delivering a consistent flow without the need for high operating speeds.

- Gentle Handling: Rotary lobe pumps are known for their ability to handle shear-sensitive fluids gently. This makes them a preferred choice for food and pharmaceutical industries, where the integrity of the liquid must be preserved.

- Self-Priming: These pumps are capable of self-priming, which means they can start operation without the need for an external priming device, making them easier to set up and operate.

- Low Maintenance: With fewer moving parts compared to other pumps, rotary lobe pumps require less maintenance. This reduces the overall downtime and increases the reliability of the system.

Applications of Rotary Lobe Pumps

Ace Lobe Pumps offers rotary lobe pumps for a wide range of industries, from heavy-duty applications to those requiring a more delicate approach to fluid handling. Below are some of the industries that benefit from rotary lobe pump technology:

Food and Beverage Industry

In the food industry, rotary lobe pumps are often used to transfer liquids, slurries, and pastes. The ability to gently handle shear-sensitive products like purees, sauces, and dairy products makes them an essential tool in food production.

Pharmaceutical Industry

The pharmaceutical industry requires highly sterile environments and precise fluid handling. Ace Lobe Pumps provide pumps that meet these exacting standards, ensuring a hygienic transfer of ingredients in the production of medicines and vaccines.

Chemical Processing

For the chemical industry, rotary lobe pumps are invaluable in handling viscous and abrasive fluids. Their robust design ensures they can handle chemicals without degrading or contaminating the product.

Wastewater Treatment

Rotary lobe pumps are ideal for transferring thick sludge and other waste materials in water treatment plants. Their self-priming feature and ability to handle solid-laden fluids make them perfect for this application.

Why Choose Ace Lobe Pumps?

When it comes to selecting a rotary lobe pump, choosing the right manufacturer is crucial. Ace Lobe Pumps stands out for several reasons:

Quality and Durability

At Ace Lobe Pumps, quality is our top priority. Our pumps are built using high-quality materials that ensure long-lasting performance even under harsh conditions. Whether you’re dealing with high-pressure systems or highly abrasive fluids, our pumps are designed to withstand the toughest challenges.

Custom Solutions

We understand that every application is unique. That’s why we offer custom-designed rotary lobe pumps that cater specifically to the needs of your business. Whether you need pumps with special sealing arrangements or different material constructions, we have the expertise to deliver a solution that fits your requirements.

Excellent Customer Support

At Ace Lobe Pumps, we are committed to providing unparalleled customer service. Our team is always available to offer technical support, troubleshooting, and maintenance assistance, ensuring that your operations run smoothly at all times.

Competitive Pricing

Despite our premium quality and custom solutions, Ace Lobe Pumps offers highly competitive pricing. We believe in delivering value for money, ensuring that you get the most cost-effective solution for your pumping needs.

Factors to Consider When Choosing a Rotary Lobe Pump

Selecting the right rotary lobe pump involves understanding various factors, such as:

- Flow Rate: Determining the required flow rate for your application will help you select the right pump size.

- Viscosity of the Fluid: The viscosity of the fluid being pumped significantly impacts the choice of pump. Heavier, more viscous fluids will require a more robust pump.

- Pressure Requirements: Depending on the system’s pressure needs, you may need a pump that can handle higher pressure levels.

- Material Compatibility: The material of construction for the pump should be compatible with the fluid being pumped to prevent corrosion or contamination.

- Maintenance: Choose a pump that is easy to maintain, as this will reduce downtime and maintenance costs.

Conclusion

Rotary lobe pumps are an essential piece of equipment for industries requiring reliable and efficient fluid transfer. From their simple yet effective working principle to their numerous advantages, these pumps provide exceptional performance across various applications. Ace Lobe Pumps offers high-quality, customized rotary lobe pumps designed to meet the specific needs of each industry.

WhatsApp Us Now

WhatsApp Us Now