Today, the primary objective of every business is operational efficiency. All hands are on deck when it comes to achieving so. As rising electricity costs have been a challenge, they are being addressed by adopting sustainable practices. While searching for the right solutions, Alternating Current (AC) drives have proven to be the reliable ones here.

It controls the speed and torque of electric motors, thereby reducing wastage, improving equipment life, and enhancing overall industrial energy efficiency. However, with multiple options for the AC drive, selecting the right one can feel tricky. Let us find out the ten most important things to consider before buying an Automation Control drive.

What are the Top 10 Things to Consider Before Buying an AC Drive?

Investing in an AC Drive requires close consideration to ensure that the system meets the high standards of reliability and efficiency set for its performance. Below are the ten most crucial factors you must consider before making your decision:

Motor Type and the Support it Requires

The motor needs to be identified upon which your drive will take charge. Other motors, including induction, synchronous, and permanent magnet motors, have unique specifications. AC drive’s incompatibility with the motor can lower efficiency or lead to breakdowns, thereby increasing maintenance costs. Therefore, getting a drive that matches the motor specifications ensures seamless operation and contributes to better industrial energy efficiency.

Importance of Load Analysis

All industrial processes include a variety of loads, such as constant torque, variable torque, or constant horsepower. Failure to design a drive load properly will lead to underperformance or high energy consumption. The proper AC drive is efficient in carrying the load and minimising the load on the motor, which increases its lifespan.

Impact of Environment

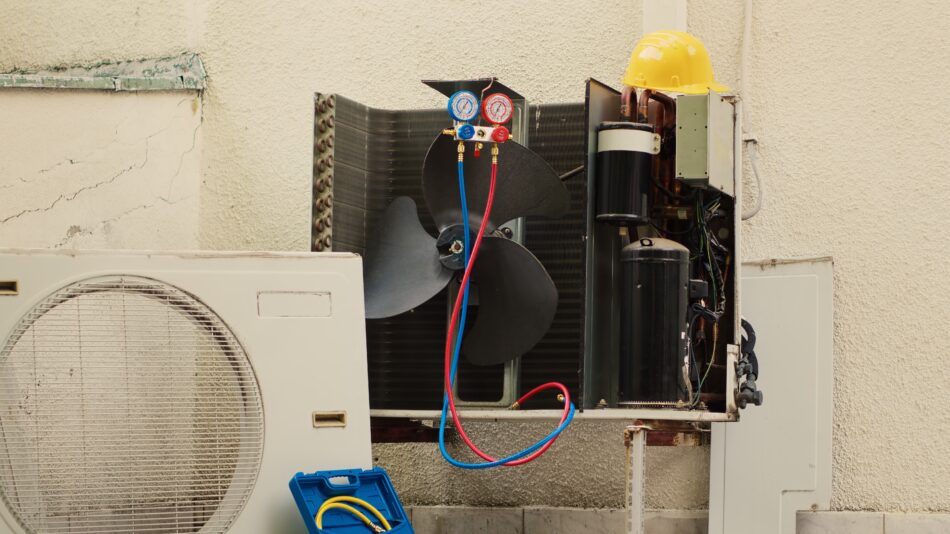

AC drives promote reduced downtime and savings on long-term maintenance expenses. At times, environmental conditions can be too harsh, such as high temperatures, dust, and excessive moisture. Such conditions are known to cause severe damage to the drive’s sensitive parts in the long run. In fact, to prevent this, extra cooling mechanisms are also used.

Voltage and Power Ratings Evaluation

A common error that is likely to occur during the AC drive purchasing process is a voltage and power mismatch. Drives operate within specific input voltages and power ranges. Now, if the motor ratings and supply are different, the whole mechanical system could trip, overheat, or get damaged permanently.

When assessing options, choose the one that best suits the electrical supply of your facility. This safeguards both industrial energy efficiency and safety.

Control and Communication Needs Assessment

Nowadays, the industries have systems that work well in integration. Consequently, considering a suitable drive for the automation system becomes crucial. Choosing a drive that integrates smoothly with the existing automation system will ensure smooth operations.

For companies focused on improving industrial energy efficiency, this level of integration is a practical step toward building smarter and more reliable systems. Moreover, you can opt for a drive that supports open communication protocol like Modbus, or Ethernet.

Role of Harmonic Distortion in Performance

Harmonics are undesirable electrical signals that may cause problems with equipment functionalities and power quality. High harmonics generated by your drive can interrupt other devices on the same power line and cause energy losses. When choosing an AC Drive with the same characteristics of harmonic mitigation, the mode will operate well and ensure that energy requirements are met. This increases reliability and also helps in lowering the costs of operation.

Energy Efficiency

A primary reason why AC drives are purchased is that they help save energy. Look for models that come with pre-installed energy optimisation features. They help adjust motor performance in real-time according to demand. Drives that reduce idle functioning and reduce power wastage enhance industrial energy efficiency significantly. While the cost may be a downside to it, the long-term savings typically outweigh the initial expense.

Ease of Maintenance and Support

All the equipment needs maintenance, no matter how sophisticated and advanced they are. AC Drives that feature built-in user friendliness, easy diagnostics, and clear error codes are relatively easier to service. Check the local service support and availability of spares as well. Selecting a brand that offers fast and efficient after-sales service ensures that, in the event of a breakdown, you will experience minimal downtime. Finally, the maintenance ease is directly related to the availability of returns on your investment.

Scalability Factor

Businesses expand, and so do their operations. For such times, selecting a suitable AC drive can help scale without incurring further expenses. Scalability saves you from frequent replacements. Drives designed with modularity and upgrade options give you flexibility and future readiness.

Total Cost of Ownership

Keeping the cost as the primary deciding factor when purchasing a drive can be misleading. There are things like installation charges, energy consumption, maintenance, downtime, etc. Purchasing an expensive drive in the beginning may offer higher efficiency and lower operating expenses. However, evaluating the total ownership cost is what contributes to both productivity and industrial energy efficiency.

Conclusion

Choosing an AC drive is a significant decision that requires a thorough analysis. By carefully evaluating all the necessary aspects, businesses can ensure a strong return on investment and achieve seamless operations.

Choosing an AC drive is a significant decision and, therefore, requires thoughtful analysis. By carefully evaluating all the necessary aspects, businesses can secure higher returns and ensure seamless operations.

Remember, the correct choice lies in how the AC drive supports your long-term objectives. For enterprises aiming to enhance performance and reliability, partnering with trusted experts like Lauritz Knudsen Electrical & Automation can make all the difference.

Read Also: 5 Essential Safety Tips for Installing Modular Switches and Sockets

WhatsApp Us Now

WhatsApp Us Now