Why Noise Reducing Casters Matter More Than Ever

In today’s demanding industrial environments, noise reducing casters have become essential. Whether it’s a busy warehouse, a high traffic hospital corridor, or a precision-driven production facility, excessive noise isn’t just irritating it can impact worker safety, productivity, and even compliance with health standards.

This guide provides a comprehensive overview of noise reducing casters for heavy duty use exploring their design, benefits, applications, and how to select the right one for your operation. You’ll gain valuable insights into what makes a caster truly quiet and how top manufacturers are revolutionizing silent mobility in industrial settings.

What Are Noise Reducing Casters?

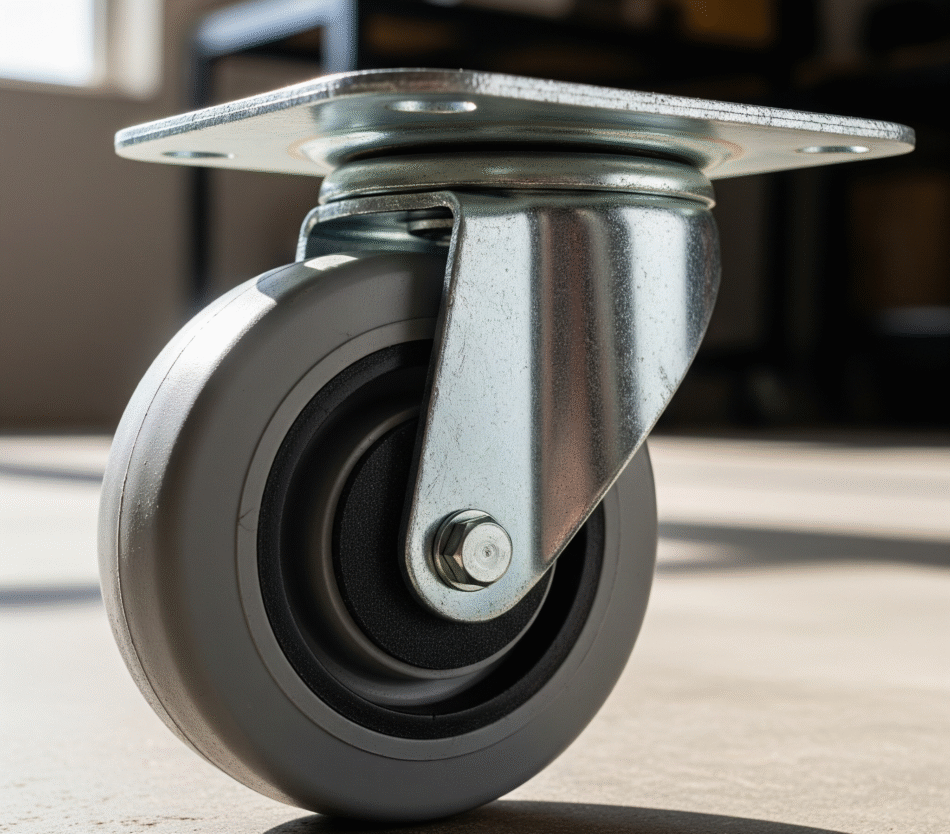

Noise reducing casters, also known as quiet rolling casters or low-noise casters, are engineered to minimize sound during transport. Unlike traditional casters made from hard materials, these utilize advanced components like polyurethane treads, precision ball bearings, and dampening cores.

These casters are designed to reduce:

- Noise from floor contact

- Rattling caused by uneven loads

- Vibration from irregular surfaces

They offer smoother, quieter motion ideal for industries that demand both high performance and low noise output.

Why Use Noise Reducing Casters in Industrial Settings?

- Workplace Safety and Hearing Protection

Excessive noise levels especially those above 85 decibels can contribute to long-term hearing loss. By integrating noise reducing industrial casters, facilities can lower environmental sound, helping protect employee hearing and reduce OSHA-related risks. - Higher Productivity and Focus

Quieter environments promote better communication and fewer distractions. Operators are more alert, responsive, and efficient when noise is minimized, especially in dynamic environments like manufacturing floors or logistics centers. - Protection for Floors and Equipment

Most heavy duty noise reducing casters are built with soft tread materials that not only minimize sound but also reduce wear on floors and vibrations that can damage delicate or precision equipment. - Better Compliance and Ergonomics

In industries like healthcare, aerospace, and electronics manufacturing, excessive noise is unacceptable. Low-noise casters help meet ergonomic goals while aligning with environmental noise regulations.

How Noise Reducing Casters Work

Advanced Materials

The core of a quiet caster is its material. Polyurethane and thermoplastic rubber treads are commonly used due to their ability to absorb shock and reduce sound during movement. These materials conform slightly to the floor, decreasing impact noise.

Precision Bearings

Most quiet and noise reducing casters incorporate sealed precision ball bearings in the wheels and swivel sections. These reduce metal-on-metal friction, prevent squeaking, and ensure a smooth, silent glide even under heavy loads.

Shock-Absorbing Design

Many casters include internal spring mechanisms or dual-wheel configurations to distribute weight more evenly. This design absorbs vibrations and reduces rolling resistance, making movement quieter and more efficient.

Applications for Noise Reducing Casters

These casters are essential across various industries:

- Manufacturing Plants – For quiet movement of heavy equipment and carts across hard concrete floors.

- Hospitals and Labs – To prevent disruption in quiet zones and patient recovery areas.

- Distribution Centers – For silent, smooth mobility across large logistics floors.

- Retail and Hospitality – Where customer experience requires quieter operations.

- Aerospace and Electronics – For protecting precision tools and reducing sensitive vibrations.

How to Choose the Right Heavy Duty Noise Reducing Casters

- Assess Load Capacity

Not all quiet casters are made equal. Evaluate your load requirements carefully. Look for noise reducing heavy duty industrial casters that are rated for the specific weights in your environment. - Consider Floor Conditions

For concrete, tile, epoxy, or delicate flooring, polyurethane-treaded casters are ideal. They provide cushioning, minimize impact, and reduce marks. - Evaluate Speed and Frequency of Use

Casters used frequently at higher speeds need more robust construction and heat-resistant materials. Ensure that the caster’s design aligns with your movement cycles. - Environment-Specific Features

For wet or chemical-prone environments, opt for casters with corrosion-resistant components and closed bearing systems. If used in medical settings, look for antimicrobial or cleanroom-compatible designs. - Explore Custom Solutions

If standard models don’t meet your performance or ergonomic needs, many manufacturers offer custom noise reducing casters designed for your specific load, noise, or space constraints.

Leading Manufacturers of Quiet Casters

When performance, durability, and low-noise design matter, several manufacturers stand out as industry leaders.

Aerol Casters: Known for advanced shock-absorbing and quiet caster technologies, engineered for extreme loads and smooth movement.

Reaction Industries: Specializes in custom polyurethane solutions that enhance noise dampening and floor protection in industrial wheels and rollers.

CasterConcepts: Offers a wide range of heavy-duty and ergonomic caster products designed to reduce noise and improve operator safety.

Conceptual Innovations: Innovators in powered and intelligent mobility solutions, including systems that reduce both manual strain and rolling noise.

These manufacturers are recognized for their commitment to quality, customization, and performance in demanding environments.

How to Make Casters Quiet – Practical Upgrades

Even if you’re not ready for a full caster replacement, small changes can significantly reduce noise:

- Lubricate your casters regularly to reduce squeaks.

- Switch to soft tread wheels if using hard plastic or metal.

- Install vibration dampeners between caster mounts and cart frames.

- Inspect and replace worn parts damaged wheels or bearings often cause unnecessary noise.

These adjustments can dramatically improve caster performance and sound levels, especially in older equipment.

FAQ: Noise Reducing Casters

Q: What makes a caster quiet?

A combination of soft tread materials, sealed bearings, and vibration-dampening design reduces both impact noise and rolling friction.

Q: Are there custom options available for noise reducing casters?

Yes. Many top manufacturers offer custom noise reducing casters tailored for specific industries, load requirements, floor types, and environmental conditions.

Q: Can heavy duty casters still be quiet?

Absolutely. Heavy duty noise reducing casters are designed to handle high loads while still offering low-noise performance using specialized materials and engineering.

Conclusion

Whether you’re looking to reduce workplace noise, enhance productivity, or protect sensitive equipment, noise reducing casters are a strategic investment. Designed with advanced materials and precision mechanics, they offer a combination of strength, silence, and smooth mobility unmatched by traditional caster solutions.

Explore quiet mobility options tailored to your environment and discover how upgrading to noise reducing casters for heavy duty use can transform your operations.