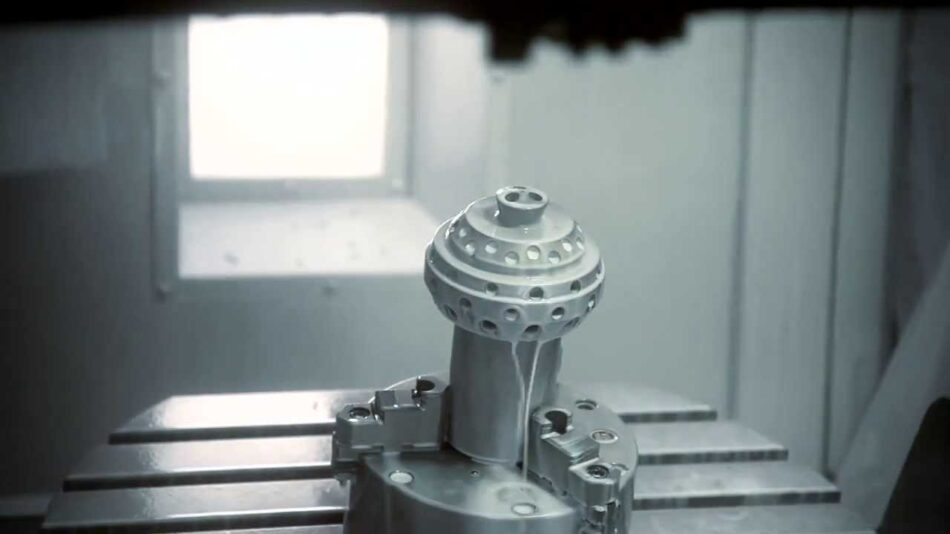

In the oil and gas sector, precision engineering plays a vital role in ensuring operational safety, efficiency, and long-term reliability. Equipment must withstand extreme temperatures, high pressures, and corrosive environments, which demands exceptional manufacturing quality. This is where oilfield part machining becomes a critical solution for producing complex components that meet exact performance standards. By using advanced CNC technology, manufacturers can deliver parts that not only fit seamlessly into large-scale systems but also maintain integrity under the most challenging field conditions.

The Importance of Precision in Oilfield Equipment

Oilfield operations rely heavily on parts that perform flawlessly under stress. From drill bits to valve components, every element must be manufactured to strict tolerances. Even a minor defect can cause equipment failure, leading to costly downtime and safety hazards. Precision machining ensures that each part is dimensionally accurate, structurally sound, and resistant to wear and tear.

One of the biggest challenges in oilfield manufacturing is material selection. Components are often made from stainless steel, titanium, or specialty alloys that are difficult to machine but necessary for strength and corrosion resistance. CNC machining excels in handling these materials with minimal waste, delivering parts that meet both strength and performance requirements.

Quality control is equally essential. Leading machining facilities use advanced inspection systems such as CMM (Coordinate Measuring Machines) and laser scanners to verify accuracy at every stage. This ensures that the finished parts are not just functional but built to last, even in offshore drilling or deep-sea exploration environments.

Subheading 1: Meeting Industry Standards and Regulations

The oil and gas industry operates under strict regulations to ensure worker safety and environmental protection. Machining companies that specialize in oilfield parts must comply with API (American Petroleum Institute) and ISO quality management standards. This compliance ensures that the parts delivered are traceable, certified, and fully documented, which is crucial for maintaining trust with clients and regulators.

Subheading 2: Reducing Lead Times and Costs

CNC machining also allows for faster turnaround times, which is essential in an industry where downtime can cost millions per day. By using automated processes, manufacturers can produce large volumes of parts without compromising quality. This efficiency not only speeds up production but also helps reduce costs by minimizing waste and rework.

Advanced CNC Technologies Driving Oilfield Machining

The advancement of CNC technology has revolutionized oilfield part production. Modern CNC machines can operate with multi-axis capabilities, allowing complex geometries to be machined in a single setup. This reduces the need for manual adjustments, improving both accuracy and efficiency.

High-speed machining, adaptive control systems, and live tooling are just some of the innovations that help manufacturers achieve optimal surface finishes and tight tolerances. These advancements also support mass customization, where different parts can be produced in small batches without sacrificing cost-effectiveness.

Another advantage of advanced CNC technology is the integration of CAD/CAM software. Engineers can design parts digitally, simulate machining processes, and optimize tool paths before production begins. This digital workflow helps identify potential issues early, reducing production delays and ensuring the final product meets specifications.

Subheading 1: Enhancing Durability Through Surface Treatments

Beyond machining, many oilfield components undergo additional treatments such as heat treatment, coating, and anodizing to improve durability. These processes enhance corrosion resistance and extend the life of parts, especially in offshore and subsea environments where exposure to saltwater and extreme pressures is common.

Subheading 2: Custom Solutions for Complex Applications

No two oilfield projects are exactly the same, and many require customized components. CNC machining allows for flexible production that can accommodate unique designs, prototype development, and low-volume runs without excessive setup times. This adaptability is critical in meeting the evolving needs of the energy industry.

Partnering with the Right Machining Service Provider

Choosing the right machining partner is key to success in oilfield part manufacturing. The ideal provider will have deep industry experience, state-of-the-art equipment, and a commitment to quality. They should also offer end-to-end support, from material sourcing to final inspection and delivery.

Communication is another important factor. Clear and consistent updates throughout the manufacturing process help ensure that deadlines are met and that any design adjustments are quickly implemented. Partnering with a company that values collaboration and transparency can make a significant difference in project outcomes.

Subheading 1: Building Long-Term Reliability

When you work with a skilled machining provider, you’re not just getting parts—you’re investing in reliability. High-quality oilfield components reduce the risk of equipment failure, improve operational safety, and extend maintenance intervals, which ultimately saves time and money.

Subheading 2: Supporting Innovation in Energy Exploration

As the oil and gas industry continues to evolve, new exploration methods and technologies will require even more advanced parts. By choosing a machining partner with cutting-edge capabilities, you position your business to take advantage of future opportunities while maintaining a competitive edge.

Conclusion – Precision Machining as the Backbone of Oilfield Operations

In the demanding world of oil and gas exploration, precision machining is more than just a manufacturing process—it’s a critical factor in operational success. From meeting stringent safety regulations to producing components that withstand the harshest environments, oilfield part machining delivers the accuracy, durability, and reliability that the industry depends on. With the right CNC partner, companies can ensure their equipment performs flawlessly, reduce costly downtime, and prepare for the challenges of tomorrow’s energy demands.