If you’ve ever worked in a warehouse or industrial facility, you know how disruptive loud caster wheels can be. Excessive noise from moving carts and equipment not only affects productivity but also poses risks to worker health and safety. That’s where noise reducing industrial casters come in.

These specialized casters are designed to minimize rolling noise while supporting heavy loads and maintaining mobility. In this guide, we’ll show you exactly how to make casters quiet using smart design choices, proper materials, and proven industrial solutions.

Why Noise Matters in Industrial Environments

Workplace noise is more than just an annoyance it’s a legitimate safety concern. According to the Occupational Safety and Health Administration (OSHA), prolonged exposure to noise levels above 85 dB can lead to hearing loss and decreased worker concentration.

How Loud Are Standard Casters?

- Traditional steel or hard-tread casters can emit 70-90 dB during movement.

- This is comparable to the sound of heavy traffic or a jackhammer.

Noise reducing casters help bring these levels down, supporting a quieter, safer, and more ergonomic workspace.

What Makes a Caster Noisy?

To effectively reduce caster noise, it’s important to understand where it comes from. The most common culprits include:

- Hard wheel materials that transmit vibration directly to the floor

- Unlubricated bearings causing friction and squeaking

- Rigid frames that amplify vibrations

- Rough or uneven floor surfaces

- Heavy loads increasing rolling resistance and floor impact

These issues are magnified in environments using heavy duty casters, where the weight and speed of movement elevate noise levels.

What Are Noise Reducing Industrial Casters?

Noise reducing industrial casters are engineered with materials and components that limit vibration, absorb shock, and reduce decibel output during motion.

Key Features:

- Soft tread wheels made of polyurethane or rubbe

- Precision bearings for smooth, quiet rolling

- Shock absorbing rigs to dampen vibration

- Ergonomic designs to reduce push/pull force and operational strain

When applied correctly, these casters can reduce noise by up to 15-20 decibels, making a major difference in compliance and comfort.

Types of Noise Reducing Casters for Industrial Use

Here’s a breakdown of the most effective low-noise casters for heavy-duty environments:

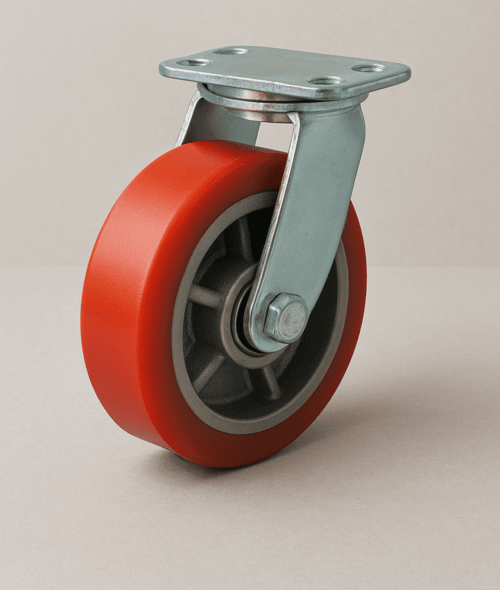

1. Polyurethane Tread Casters

- Softer than metal or hard plastic

- Absorbs minor vibrations and floor impact

- Ideal for uneven surfaces and high-speed movement

- Often used in quiet rolling casters for hospitals and cleanrooms

2. Rubber on Aluminum Core Wheels

- Offer excellent sound dampening

- Maintain strength without sacrificing quietness

- Best suited for noise reducing heavy duty industrial casters

3. Shock Absorbing Casters

- Equipped with built-in industrial shock absorbers

- Handle heavy loads while reducing jarring impacts

- Common in warehouses, manufacturing plants, and aviation environments

4. Custom Noise Reducing Casters

When off-the-shelf options won’t do, custom noise reducing casters offer tailored materials, wheel diameters, load capacities, and sound-absorbing features to meet specific operational requirements.

How to Make Casters Quiet: Practical Steps

If you’re wondering how to make casters quiet, here are proven solutions:

Choose the Right Wheel Material

- Opt for soft-tread wheels like polyurethane or thermoplastic rubber

- Avoid metal-on-metal contact, which amplifies sound

Lubricate Bearings Regularly

- Use high-quality grease on caster bearings to minimize squeaks and friction

- Replace worn bearings to maintain quiet performance

Maintain Floor Surfaces

- Smooth floors reduce vibration and wheel chatter

- Patch cracks and eliminate debris for optimal results

Install Shock Absorbing Mounts

- Especially effective for heavy duty noise reducing casters

- Absorb vertical and horizontal shock, improving both noise and durability

Consider Dual-Wheel Designs

- Dual wheels distribute weight more evenly and reduce pressure points

- Leads to smoother and quieter operation

Benefits of Quiet and Noise Reducing Casters

Switching to quiet and noise reducing casters brings tangible improvements across operations:

- Health & Safety: Protect workers from noise-induced hearing loss

- Productivity: Less distraction, clearer communication, and better focus

- Compliance: Helps meet OSHA and local noise regulations

- Brand Image: A quieter facility reflects operational professionalism

- Long-Term Savings: Reduces wear and tear on floors and equipment

When to Use Heavy Duty Noise Reducing Casters

Some environments demand both strength and silence. That’s where noise reducing heavy duty industrial casters make a big impact.

Use Cases:

- Aerospace and defense manufacturing

- Hospitals and healthcare facilities

- Automated Guided Vehicles (AGVs)

- Warehousing and fulfillment centers

- Cleanrooms and laboratories

Combining industrial noise reducing casters with custom shock absorption ensures both performance and quietness under extreme demands.

Frequently Asked Questions (FAQ)

What are the best materials for low-noise casters?

Polyurethane and rubber are the best materials for low-noise casters, thanks to their ability to absorb vibration and reduce floor impact noise.

How do I maintain quiet rolling casters?

Regular lubrication, checking for debris, and replacing worn bearings or wheels will keep quiet rolling casters operating silently.

Can custom casters really reduce noise?

Yes. Custom noise reducing casters can be engineered with specific materials, bearings, and shock absorption systems that significantly reduce decibel output and meet your exact needs.

Conclusion

Loud caster wheels are more than just a nuisance they impact safety, productivity, and compliance. By switching to noise reducing industrial casters, you create a quieter, safer, and more efficient work environment. Whether you’re using heavy duty noise reducing casters or opting for custom noise reducing casters, the right solution can transform your facility.

Ready to quiet down your operation? Explore industrial caster options that prioritize performance and peace.