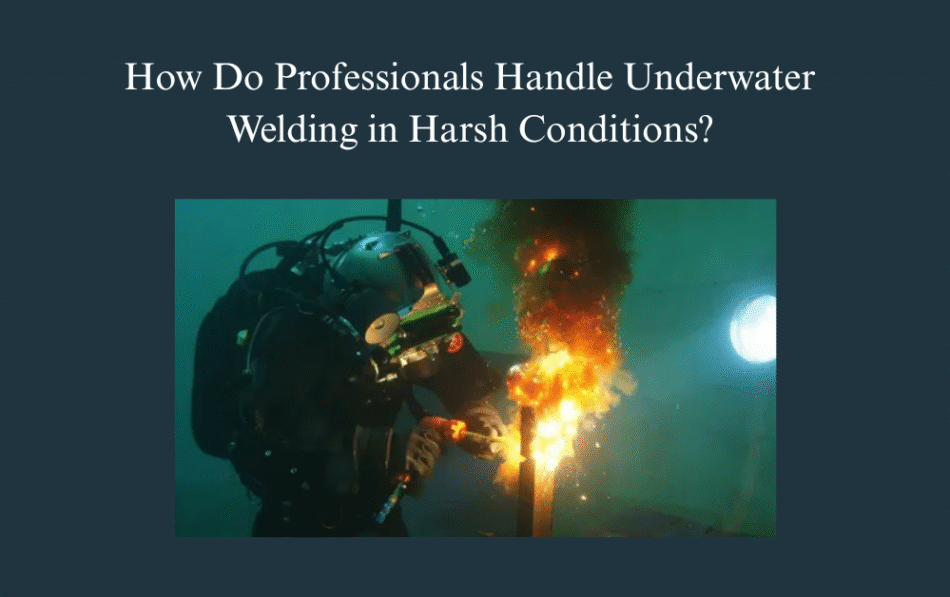

Underwater welding is one of the most challenging jobs in the world. It’s done deep underwater, often in risky and difficult environments. Professionals who do this job have to deal with cold water, strong currents, low visibility, and high pressure. In this blog, we’ll explain how underwater welders handle these harsh conditions and complete their work safely and effectively.

We’ll break down the tools they use, the training they need, the safety steps they follow, and how they solve problems underwater. Let’s dive into this topic step-by-step in simple words.

Note : Looking for reliable underwater cutting and welding services in UAE? Get in touch with our expert team today to handle your marine repairs and welding needs safely and professionally. Contact us now and let’s get your project done right!

What Is Underwater Welding and Where Is It Used?

Underwater welding means joining metal parts underwater

Underwater welding is when two or more pieces of metal are joined together below the surface of the water. This work is done by trained divers who are also skilled welders.

Common places where underwater welding is needed

- Ships and boats – Fixing or maintaining damaged ship parts.

- Oil and gas platforms – Repairing structures used for drilling oil in the ocean.

- Bridges and dams – Welding is done on underwater parts of bridges or water dams.

- Pipelines – Fixing water or gas pipelines that run under rivers or seas.

What Makes Underwater Welding So Difficult?

Underwater welding is much harder than welding on land

Welding underwater brings extra challenges that are not there on dry land. Let’s understand why it is so hard.

1. Water pressure increases with depth

The deeper the welder goes, the more pressure they feel. This can affect their tools and their body.

2. Cold water affects the welder and the equipment

In deep water, it gets very cold. Cold temperatures can make the welder tired quickly and can damage tools if not handled well.

3. Limited visibility underwater

It is hard to see clearly underwater, especially at greater depths. Murky water, darkness, or floating particles can make it difficult for welders to see what they are doing.

4. Risk of electric shock

Since welding uses electricity, there is always a risk of electric shock when welding in water. Welders have to be extra careful to avoid accidents.

5. Breathing equipment adds difficulty

Welders have to wear diving suits and breathing gear, which can be heavy and uncomfortable. This gear also limits their movement and makes it harder to work.

Types of Underwater Welding Used by Professionals

There are two main methods of underwater welding

1. Wet welding – Welding directly in the water

In wet welding, the welder performs the job while being fully submerged in water. The tools and the welding arc are also in direct contact with the water.

- Used for quick repairs

- Less costly

- Riskier due to water and electricity contact

2. Dry welding – Welding inside a dry chamber

In this method, a special dry room or chamber is placed underwater. The water is pushed out with gas, and welding happens in a dry space. This chamber is called a habitat.

- Safer and better quality

- More expensive

- Takes longer to set up

What Tools and Equipment Do Underwater Welders Use?

Special tools are needed to work underwater

1. Waterproof welding machine

A machine that is designed to work safely underwater without causing electric shocks.

2. Welding rods that burn underwater

Welding rods or electrodes are made to burn even in water. They create a strong bond between metals.

3. Diving suits and helmets

Welders wear thick diving suits and helmets that provide oxygen and keep them warm.

4. Communication system

Welders often use a wired radio system in their helmets to talk to their team above water.

5. Lights and cameras

Because of poor visibility, lights and underwater cameras help welders see their work more clearly.

What Kind of Training Do Underwater Welders Need?

Training is a must for safety and success

1. Certified diver training

First, the person must be trained and certified as a commercial diver. This teaches them how to breathe underwater, control buoyancy, and handle emergencies.

2. Welding training

Next, they need welding training. They must learn different welding techniques and how to apply them underwater.

3. Special underwater welding courses

Some schools offer special courses just for underwater welding. These teach how to use underwater tools, work in low light, and follow safety steps.

4. Physical and mental fitness

Underwater welding is tough, so welders must be strong, healthy, and able to stay calm under pressure.

How Do Professionals Stay Safe While Welding Underwater?

Safety is the most important part of the job

Underwater welding is risky. Professionals follow many steps to keep themselves safe.

1. Pre-dive checks

Before diving, the welder and the team check all equipment – suits, breathing gear, welding tools, and power sources.

2. Always work in teams

A welder never dives alone. There’s always a dive partner or a surface team watching and ready to help in case of trouble.

3. Limit dive time

Welders do not stay underwater too long. Their time is carefully watched to avoid getting sick from pressure changes.

4. Watch for gas buildup

Welding underwater creates gas bubbles. If these collect in closed areas, they can explode. Proper ventilation is always used.

5. Avoid electric shocks

All tools are insulated. Welders follow strict rules to prevent contact between water and live wires.

6. Emergency plans are ready

The team is trained to act fast in emergencies. If something goes wrong, they know how to bring the welder to the surface safely.

What Problems Do Underwater Welders Face in Harsh Conditions?

Problems are common, but professionals are trained to solve them

1. Currents moving the welder

Strong water currents can move the welder or make it hard to hold tools steady. Welders use weighted belts and hand grips to stay in place.

2. Tools not working properly

Cold and pressure can affect tools. Welders always carry backup tools and know how to fix problems quickly.

3. Low visibility

In dirty or deep water, it’s hard to see. Welders rely on cameras, special lights, and even touch to do their job.

4. Fatigue and body stress

Welding underwater is exhausting. Welders take regular breaks and follow a strict dive schedule to stay healthy.

How Do Welders Prepare Before Going Underwater?

Planning and practice are key to success

1. Study the job

Before diving, the team studies blueprints, pictures, and previous reports to understand the task.

2. Prepare the site

Any loose objects or dangers are removed from the work area. The water may be cleared of mud or debris if needed.

3. Test the equipment

Everything is tested – the welding machine, the cables, the suit, and the oxygen tanks.

4. Practice on land

Sometimes, welders practice the same task on land before doing it underwater. This helps them avoid mistakes later.

How Is the Work Checked After Welding Is Done?

The final step is inspection and approval

1. Visual check

Underwater cameras or diving inspectors look closely at the weld to check for cracks or weak spots.

2. Non-destructive testing (NDT)

This is a method where the weld is tested without breaking it. Tools like ultrasonic machines or magnetic devices are used.

3. Pressure testing

If the welded part needs to hold water or gas, it is tested by filling it and checking for leaks.

Final Thoughts: Why Underwater Welding Needs Skilled Professionals

Underwater welding is not a job for just anyone. It needs proper training, good health, and a brave heart. The work is tough, and the environment is harsh, but skilled professionals are trained to handle it all. They use the right tools, follow safety rules, and work in teams to make sure the job is done right.

If you’ve ever wondered how underwater structures like oil platforms, bridges, or pipelines stay in good condition, it’s thanks to the amazing work of underwater welders.

Do You Want to Learn More About Underwater Welding?

Let us know! We’d be happy to share more details or answer your questions. Whether you’re curious or planning a career in this field, it’s always good to understand how professionals handle such tough jobs.

For more insightful articles related to this topic, feel free to visit : thestarbiznews.

WhatsApp Us Now

WhatsApp Us Now