The manufacturing industry has entered an era where speed, accuracy, and efficiency are more important than ever. To meet these demands, many companies have turned to CNC Machining, a technology that combines computer programming with advanced tools to create precise and complex components. Unlike traditional manual methods, CNC machining allows for consistent production at scale, saving both time and resources. From aerospace to healthcare, industries across the globe are relying on this technology to stay ahead in an increasingly competitive market. Understanding its benefits, applications, and future is crucial for businesses aiming to grow.

The Evolution of CNC Machining

From Manual Labor to Digital Control

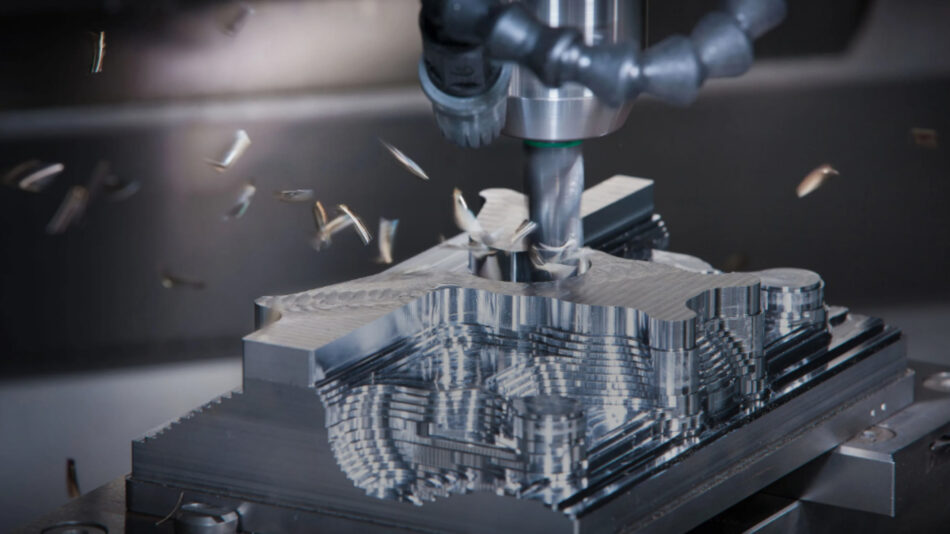

In the past, manufacturing depended heavily on manual labor and basic machinery. Skilled operators shaped parts by hand, but the process was slow and often lacked consistency. CNC machining changed that completely by introducing computer numerical control. This system translates digital designs into precise movements, guiding cutting tools with incredible accuracy.

How CNC Reshaped the Industry

The shift from manual processes to CNC machining allowed companies to achieve faster production cycles and higher reliability. Instead of producing just a few accurate parts, manufacturers can now replicate thousands of identical components without variation. This ability has redefined what is possible in modern manufacturing.

Core Benefits of CNC Machining

Precision That Sets the Standard

CNC machining is valued for its ability to deliver tolerances measured in microns. Whether creating turbine blades, engine parts, or surgical instruments, this precision ensures that every component meets strict quality standards. For industries where safety and durability matter most, such as aerospace and healthcare, this accuracy is non-negotiable.

Efficiency and Cost Savings

Automation reduces the chance of human error and speeds up production. Although the initial setup requires investment, CNC machining quickly proves cost-effective by minimizing waste and lowering labor expenses. The result is higher output with reduced operational costs—an advantage that appeals to businesses of all sizes.

Applications of CNC Machining Across Industries

Aerospace and Automotive Applications

The aerospace sector demands lightweight yet strong components, and CNC machining delivers both. Complex parts like engine housings and turbine blades must endure extreme conditions, and CNC technology ensures reliability. Similarly, the automotive industry depends on CNC-machined components such as brake systems, gears, and engine blocks, where consistency directly impacts performance and safety.

Medical and Consumer Product Uses

Healthcare has benefited immensely from CNC machining. Custom implants, prosthetics, and surgical instruments require extreme accuracy, which this technology provides. In the consumer market, CNC machining plays a role in producing electronics, home appliances, and luxury goods, where quality finishes and durability enhance customer satisfaction.

Why Choose MYT Machining as Your CNC Partner

A Commitment to Quality and Innovation

Among the many providers in the market, MYT Machining has established itself as a trusted name. With advanced equipment and a team of experts, the company consistently delivers high-quality results. Their ability to tailor solutions ensures that every client receives products designed to meet their unique requirements while maintaining cost efficiency.

The Future of CNC Machining

As industries adopt smart factories, CNC machining is evolving further. Integration with artificial intelligence and the Internet of Things will create machines capable of predictive adjustments, improving accuracy and reducing downtime. By embracing these advancements, companies can position themselves at the forefront of innovation. MYT Machining is already preparing for this future, making it a reliable partner for long-term growth.

Conclusion

Manufacturing has advanced beyond traditional limits, and CNC Machining is leading the way. Its combination of accuracy, speed, and flexibility makes it a vital tool across industries ranging from aerospace to healthcare. By reducing costs, minimizing errors, and enabling complex designs, CNC technology empowers businesses to remain competitive in a global marketplace. For organizations ready to scale production while maintaining high standards, CNC machining is not just a solution—it is a necessity. Embracing this technology today ensures success tomorrow, and those who partner with trusted providers will stay ahead in an evolving industry.