1. Introduction

Corrosion is a major challenge in industries that rely on metal components, as it can lead to product damage, financial losses, and safety hazards. Anti-corrosive packaging plays a vital role in preventing rust and degradation, ensuring that products remain intact during storage and transportation. With industries such as automotive, electronics, and aerospace growing rapidly, the demand for effective corrosion protection solutions is at an all-time high.

To Know More Visit: https://www.databridgemarketresearch.com/reports/global-anti-corrosive-packaging-market

The anti-corrosive packaging market has witnessed significant expansion, driven by technological innovations and a growing focus on sustainability. As businesses look for cost-effective, durable, and eco-friendly packaging options, manufacturers are investing in advanced materials and smart packaging solutions to meet these evolving needs.

2. Understanding Corrosion and Its Impact

Corrosion is the natural process by which metals degrade due to environmental factors like moisture, oxygen, and chemicals. This phenomenon leads to rust, weakening the structural integrity of products and machinery.

How Corrosion Affects Industries:

- Automotive: Rusting of car parts can lead to costly repairs and replacements.

- Electronics: Corrosion can damage circuit boards and reduce the lifespan of electronic devices.

- Aerospace: Aircraft components exposed to corrosion may compromise passenger safety.

- Heavy Machinery: Industrial tools and metal parts degrade faster without proper protection.

Anti-corrosive packaging is essential to prevent such damages, ensuring products maintain their functionality and durability over time.

3. What is Anti-Corrosive Packaging?

Anti-corrosive packaging refers to specialized materials and techniques designed to protect metal-based products from oxidation and rust formation. These packaging solutions extend the shelf life of products, reduce maintenance costs, and prevent financial losses due to corrosion-related damages.

Key Benefits of Anti-Corrosive Packaging:

- Protects against moisture, chemicals, and environmental pollutants

- Reduces the need for frequent product replacements and repairs

- Enhances the longevity and quality of metal components

- Minimizes costs associated with corrosion-related damages

4. Types of Anti-Corrosive Packaging

Several types of anti-corrosive packaging are used across industries, each serving different protective purposes:

1. VCI (Volatile Corrosion Inhibitor) Packaging

- Uses chemical compounds that create a protective layer on metal surfaces.

- Common forms: VCI bags, films, papers, and foams.

- Ideal for automotive, aerospace, and machinery industries.

2. Barrier Packaging

- Utilizes multi-layer films and coatings to block moisture and contaminants.

- Common materials: Aluminum foil laminates, polymer coatings.

- Used for long-term storage and transportation.

3. Desiccant Packaging

- Absorbs moisture to prevent condensation and humidity damage.

- Examples: Silica gel packets, activated clay, calcium chloride.

- Frequently used in electronics, pharmaceuticals, and military applications.

4. Rust Preventive Oils and Coatings

- Liquid coatings applied to metal surfaces to prevent oxidation.

- Examples: Petroleum-based coatings, bio-based rust inhibitors.

- Used in machinery and industrial metal components.

5. Materials Used in Anti-Corrosive Packaging

To effectively protect products, manufacturers use different materials, each offering unique benefits:

1. Plastic-Based Materials

- Polyethylene (PE), Polypropylene (PP), and PET are commonly used for VCI films and wraps.

- Lightweight, durable, and resistant to moisture.

2. Paper-Based Materials

- VCI-treated papers are eco-friendly alternatives to plastic.

- Used for wrapping metal components in automotive and electronics industries.

3. Metal-Based Coatings

- Aluminum and zinc coatings provide a robust barrier against rust.

- Often used in industrial machinery packaging.

4. Bio-Based and Eco-Friendly Alternatives

- Plant-based corrosion inhibitors and biodegradable films are gaining popularity.

- Reduces environmental impact while maintaining effective corrosion protection.

6. Market Dynamics and Growth Factors

Several factors drive the growth of the anti-corrosive packaging market:

- Increasing Industrialization: Growth in automotive, aerospace, and heavy machinery industries boosts demand.

- Technological Advancements: Innovations like smart packaging and nanotechnology improve corrosion protection.

- Sustainability Trends: Rising demand for biodegradable packaging materials.

- Government Regulations: Strict anti-corrosion guidelines encourage businesses to adopt protective packaging.

7. Challenges in the Anti-Corrosive Packaging Market

Despite its advantages, the market faces key challenges:

- High Costs: Advanced materials like VCI films and coatings can be expensive.

- Limited Awareness: Small businesses in developing regions may not fully understand corrosion protection benefits.

- Environmental Concerns: Plastic-based anti-corrosive packaging contributes to pollution, driving demand for greener alternatives.

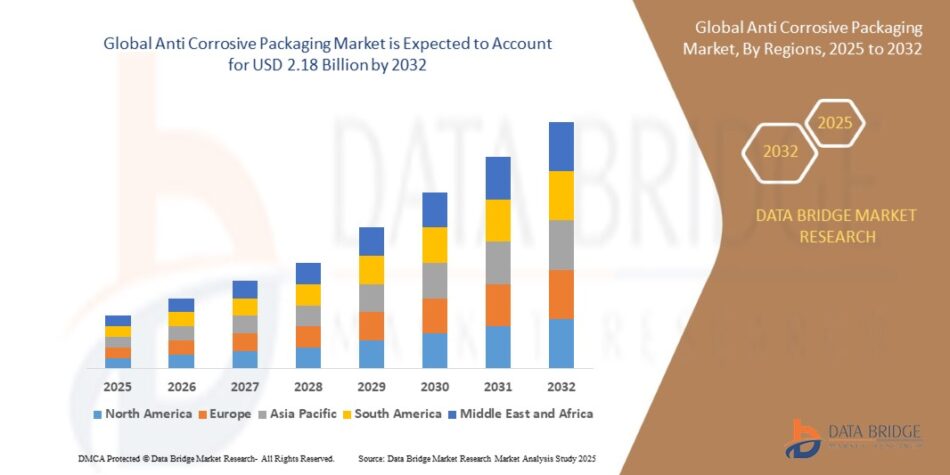

8. Regional Analysis of the Market

The anti-corrosive packaging market varies across different regions:

- North America: Strong industrial base and focus on innovation.

- Europe: High adoption of sustainable and eco-friendly packaging solutions.

- Asia-Pacific: Rapid industrialization and increasing demand for cost-effective packaging.

- Rest of the World: Emerging opportunities in Latin America and Africa due to industrial growth.

Conclusion

The anti-corrosive packaging market is expanding due to growing industrial needs and technological advancements. With a strong focus on sustainability, companies are investing in biodegradable and eco-friendly solutions to reduce environmental impact. As industries continue to evolve, innovative packaging methods will play a crucial role in ensuring product longevity and reducing corrosion-related losses.

FAQs

- What industries benefit the most from anti-corrosive packaging?

- Automotive, aerospace, electronics, heavy machinery, and military sectors.

- What is VCI packaging, and how does it work?

- VCI packaging releases protective vapors that prevent metal surfaces from rusting.

- Are there eco-friendly alternatives to traditional anti-corrosive packaging?

- Yes, biodegradable films and plant-based corrosion inhibitors are sustainable options.

- How can businesses reduce costs while using anti-corrosive packaging?

- By optimizing packaging design, bulk purchasing, and using cost-effective alternatives like VCI paper.

- What are the future trends in anti-corrosive packaging?

- Smart packaging, AI integration, and expansion of sustainable materials.

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-tuna-market

https://www.databridgemarketresearch.com/reports/global-bare-metal-stents-market

https://www.databridgemarketresearch.com/reports/global-wound-debridement-market

https://www.databridgemarketresearch.com/reports/global-glycogen-synthase-kinase-3-beta-gsk-3-inhibitors-therapeutics-market

https://www.databridgemarketresearch.com/reports/global-transit-station-display-boards-market