Air pollution is now one of the most significant environmental challenges facing humanity today. Air quality is compromised by industrial emissions, exhaust fumes, and dust from construction work. Amidst growing regulatory pressure and increasing demand for sustainable solutions, Electrostatic Precipitators (ESPs) have become a prevalent technology in the field of industrial air cleaning. But beyond simply removing particulate matter, the question that arises is: Can ESPs also save energy by cleaning the air? In the following sections, we examine how electrostatic precipitators operate, as well as their applications and benefits.

Understanding Electrostatic Precipitators

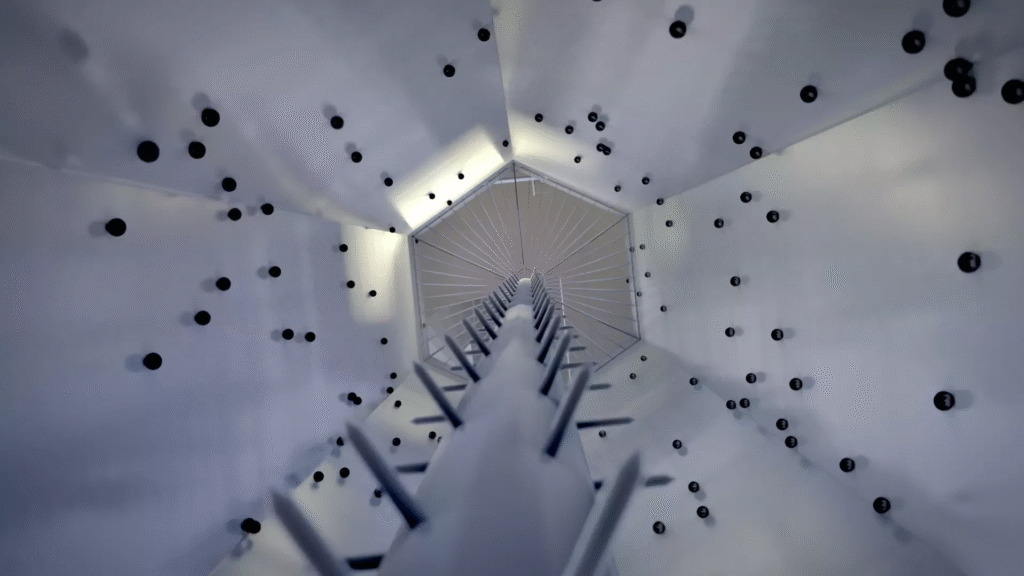

Electrostatic Precipitators are devices for removing fine particles from gas streams using the electrostatic force. It is distinct from typical filters in that ESP uses electrical energy to charge dust particles before collecting them on charged plates.

Its principle of operation is quite simple:

- Particle Ionization: As the dirty gas flows through an ESP, high-voltage electrodes generate a corona that imparts a negative charge to suspended particles.

- Collection: Charged particles move to the collection plates with a positive charge and are retained on the surface.

- Cleaning: At regular intervals, these plates are mechanically cleaned (via rapping/vibration) to dislodge the collected dust and maintain uninterrupted flow.

ESPs are frequently utilized in power plants, the cement industry, the steel industry, and the chemical industry to efficiently remove dust particles from high-temperature gases.

The Energy Consumption Factor

Although they are very efficient for collection, ESPs require large amounts of energy. The system demand is due mainly to two reasons:

- High-Voltage Power Supply: To maintain the corona discharge, it an electrical power is required. The voltage and current are usually related to the gas flow rate and particle concentration.

- Mechanical Cleaners: Continuous or intermittent ‘rapping’ of collecting plates consumes more energy, albeit far less than required for ionization.

However, in many cases, ESPs use less energy than other air-cleaning techniques, especially when used for the treatment of very large volumes of gas with relatively high dust loadings.

NOTE:- Industries in the region adopted electro static precipitators in UAE to minimize harmful emissions. The systems were praised for their energy-saving features and low maintenance. Airody Trading LLC delivered expert support and high-quality equipment. To enhance your air purification systems, reach out to Airody Trading LLC for expert solutions.

Comparing ESPs to Conventional Air Cleaning Technologies

To evaluate the energy efficiency, ESPs must be compared to other air-cleaning systems:

Mechanical Filters

Mechanical filters (such as HEPA filters and baghouses) utilize a physical medium to capture particulates. Although high removal efficiencies can be reached:

- Filter pressure drop increases with particle loading, requiring additional fan energy.

- Often, filter changes are required by the lifespan of the material media, creating waste and incurring additional operational expenses.

- Enormous amounts of gas require a burst of energy demand.

In comparison, ESPs have low-pressure drops, even with high particulate loadings, which often result in substantial cost savings for the industry.

Wet Scrubbers

Wet scrubbers pass the polluted air through a liquid spray to remove toxins. They work better for some particles and gases, but:

- Expend water to keep the liquid flowing.

- Highly energy-consuming treatment and transportation of contaminated liquids.

- Increased corrosion and maintenance costs.

As a dry system, ESPs operate without the complications of liquid handling and are often more energy-efficient in terms of electricity consumption.

Innovations Enhancing ESP Energy Efficiency

Recent developments in technology have made ESPs more energy efficient than ever before:

- CEE-Enabled Advanced Control System: Real-time voltage and current sensing enable superior power management, resulting in reduced energy consumption.

- VFDs – Variable Frequency Drives: Variable frequency drives adjust the speed of the fan and gas flow offsets to reduce energy use without sacrificing particulate removal.

- Hybrids: ESPs can also be used as a hybrid system with fabric filters, which maximizes removal efficiency while minimizing overall energy consumption.

- Enhanced Electrode Design: State-of-the-art electrode layouts minimize power loss while maintaining a high particle collection force.

Environmental and Economic Benefits

Environmental and economic benefits of ESPs. The reduction in energy consumption shown above has direct environmental and economic advantages:

- Reduced Carbon Footprint: The reduced use of electricity results in fewer greenhouse gases being released during power generation.

- Operational Cost Efficiency: Effective ESPs reduce the electricity consumption of industrial plants, leading to cost-effective long-term operation.

- Compliance: ESPs offer efficient particle collection and lower energy consumption, which enables industries to comply with more stringent air pollution control regulations at a reduced cost.

Factors Affecting Energy Efficiency in ESPs

However, they have several limitations, and the real ESP’s energy saving potential is based on a number of parameters:

- Gas Flow: If higher quantities of gas are used, more current is required to fully charge the atomised particles.

- Size Matters: Capturing Fine Particles. Finer particles are more difficult to capture and require higher voltages to capture.

- Maintenance: Frequent cleaning of electrodes and collection plates to achieve minimal power loss for uniform performance.

- Environment: The dried air temperature and humidity level may influence the efficiency of corona discharge, thereby affecting energy consumption.

Designing and running those systems properly is thus very important to achieve the energy-saving effects of ESPs.

Case Studies Highlighting Energy Efficiency

Examples of industries where ESPs have shown energy reduction include the following:

- Power Generation: Contemporary coal power plants with ESPs consume lower fan electricity than do the facilities using baghouse technology. Particle consistency higher than 99% is retained.

- Cement: ESP retrofits can reduce a cement plant’s electricity consumption by 10–15% when compared to conventional filtration techniques.

- Steel: Hybrid ESP and fabric filter technology that minimises energy requirement and satisfies tough environmental standards.

These cases demonstrate that ESP, when designed properly, can be beneficial in terms of environmental and energy aspects.

Limitations and Considerations

Although ESPs can provide substantial energy-saving potential, they do have limitations:

- Initial Investment: Advanced ESP systems are an investment, but German bank accounts usually diminish the payback period.

- Performance in Sticky or High-Moisture Particles: If the particle is sticky or has a high moisture content, it will lower efficiency and increase the energy required to remove these particles, thereby maintaining performance.

- Space: Large ESPs require a significant amount of space, which is not practical for every installation.

Despite these difficulties, ESPs remain a viable option for applications where air quality and energy usage are of utmost concern.

Conclusion

Electrostatic Precipitators aren’t just air cleaners – they’re an important tool for sustainable industrial work processes. Due to the limited use of mechanical filtration and the application of electrical forces, ESPs can still achieve high dust removal efficiency with lower energy consumption. Developments in control systems, electrode configurations, and hybrids enhance the value of their energy-saving capabilities.

For sectors wishing to strike that crucial balance between being regulation-compliant, energy-efficient, and environmentally friendly, then investment in electronic phase converters is a smart move. It is a stalwart in the game of energy-efficient air pollution control, but requires good design, care, and maintenance to reach its long-term benefits of lower energy usage, a smaller carbon footprint, and reliable air-cleaning capabilities.

For more insightful articles related to this topic, feel free to visit – thestarbiznews