In recent years, Taiwan has emerged as a critical player in the global electronics supply chain, with its Printed Circuit Board (PCB) industry standing at the forefront of this transformation. As global demand for advanced electronics accelerates—fueled by 5G, electric vehicles (EVs), artificial intelligence (AI), and Internet of Things (IoT)—Taiwan’s PCB sector is attracting significant investment. But what exactly is driving this growth, and why is Taiwan becoming such a hotbed for PCB development?

This article explores the multifaceted reasons behind the surge in investment, examining the technological, economic, and strategic factors shaping Taiwan’s position in the global PCB industry.

A Mature Yet Evolving Industry

Taiwan’s PCB industry is far from new. The country has been a major supplier of PCBs for decades, boasting a well-established supply chain and highly skilled workforce. Taiwan’s PCB makers produce a wide variety of boards, from single-sided to complex multi-layered and high-density interconnect (HDI) PCBs. However, the industry has not remained static. Over the past few years, Taiwanese manufacturers have ramped up R&D, streamlined fabrication processes, and invested heavily in cutting-edge technologies to meet the rapidly changing demands of global markets.

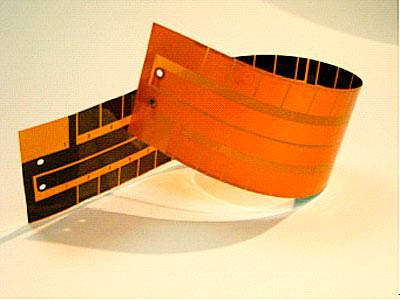

One of the most prominent trends driving investment is the global push for high-performance computing and miniaturization. This demand is being met with innovations such as Rigid-Flex PCBs, which offer the flexibility of flexible circuits and the stability of rigid boards. This hybrid design is especially critical for modern devices requiring both reliability and space-saving layouts, such as smartphones, wearables, and automotive electronics. For More Information, visit this.

Strategic Government Support

Taiwan’s government has played a pivotal role in supporting the PCB industry’s growth. With an eye on global competitiveness, various initiatives have been introduced to foster innovation, workforce development, and green manufacturing. Tax incentives and grants have encouraged domestic companies to upgrade facilities and adopt more sustainable production practices.

Moreover, Taiwan’s robust industrial clusters provide manufacturers with ready access to suppliers and services. The proximity to other critical components of the semiconductor and electronics industries enables efficient collaboration, driving cost-effectiveness and faster time-to-market.

Surge in Global Demand for High-End Electronics

A key catalyst for new investments in Taiwan’s PCB sector is the exponential growth in end-user industries, especially in areas like automotive electronics, telecommunications, and healthcare devices. Electric vehicles, for instance, require complex PCBs to support battery management systems, infotainment units, and advanced driver-assistance systems (ADAS). As the EV market grows, so too does the demand for high-reliability PCBs.

Similarly, the expansion of 5G infrastructure is creating a need for PCBs that can handle higher frequencies and more complex circuitry. Taiwanese manufacturers have responded by developing advanced materials and techniques to meet the stringent performance requirements of 5G applications.

International Partnerships and Diversification

In light of geopolitical tensions and supply chain disruptions, global companies are seeking to diversify their manufacturing bases. Taiwan, with its strong infrastructure and technological expertise, has become a favourable destination for strategic partnerships and contract manufacturing. Investments are not just flowing from domestic firms but also from international tech giants looking to hedge risks and secure a reliable PCB supply.

This has created opportunities for Taiwanese firms to expand their capabilities through joint ventures, licensing agreements, and acquisitions—further strengthening the sector’s global standing.

Digital Transformation and Smart Manufacturing

To remain competitive, Taiwanese PCB manufacturers are embracing digital transformation. Industry 4.0 technologies—such as AI-driven process optimization, real-time data analytics, and automation—are being integrated across production lines. These innovations reduce downtime, improve product quality, and enhance manufacturing efficiency.

This evolution has made the sector more attractive to investors, as companies that adopt smart manufacturing practices often show better returns, operational resilience, and scalability.

Emphasis on Sustainability and Green Technologies

Environmental consciousness is no longer optional in the manufacturing world. Taiwan’s PCB sector is taking proactive steps to minimize its environmental footprint. Investments are being directed toward eco-friendly materials, waste reduction systems, and energy-efficient equipment. Compliance with international standards such as RoHS and REACH has become a norm, making Taiwanese PCBs more appealing to environmentally conscious markets.

Sustainability isn’t just good for the planet—it’s also good for business. Companies that demonstrate a commitment to environmental responsibility often gain a competitive edge in international tenders and build stronger relationships with ESG-focused clients.

Opportunities and Challenges Ahead

While Taiwan’s PCB industry has strong momentum, it is not without its challenges. Rising labor and energy costs, global competition, and raw material shortages pose ongoing threats. However, Taiwan’s adaptive and resilient manufacturing ecosystem continues to mitigate these risks through innovation, strategic planning, and investment in talent.

The global PCB market is expected to grow at a steady pace, and Taiwan is well-positioned to capitalize on this trend. Whether through its advancements in PCB Fabrication Taiwan, strategic government backing, or its integration with cutting-edge technologies, the island nation’s PCB sector is clearly moving in the right direction.

Conclusion

The convergence of technology, global demand, strategic partnerships, and government policy has created an ideal environment for investment in Taiwan’s PCB sector. As the world increasingly relies on smarter, faster, and more efficient electronics, Taiwan is proving itself to be not just a participant—but a leader—in the PCB evolution.

For businesses looking to enter the market or source reliable PCB solutions, Taiwan offers a wealth of opportunities, backed by decades of experience and a forward-thinking approach.

To explore professional PCB manufacturing and fabrication services, visit Pcb-Togo Electronic, Inc—a trusted provider offering comprehensive PCB solutions tailored to modern industry needs.

WhatsApp Us Now

WhatsApp Us Now