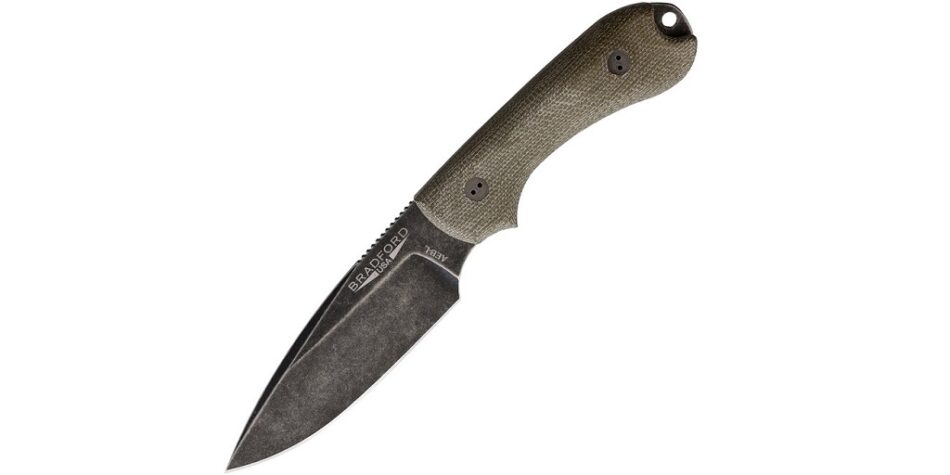

If you haven’t heard of Bradford Knives yet, made by Brad Larkin in the United States, and indicative of traditional American quality, it might be time to change that.

Whereas other knife manufacturers are (by and large) chasing trends and visibility, Brad Larkin and his namesake Bradford Knives are committed to pursuing something much simpler: tactical and EDC fixed blades that are basic but effective.

Here are 3 ways they break the mold.

Design Aesthetics (or Lack Thereof)

There are some that can’t stand simplicity; others think that the beauty of a thing is tied to how effectively it can accomplish its purpose without any non-value added eccentricities.

Bradford Knives exemplify the latter viewpoint. Yes, they are simple, and their blade profiles and handle designs are never going to be exalted for looks alone.

But who’s out here buying a knife (or reviewing it) on looks alone? That’s perverse.

These knives are designed to stand up to the rigors of hard use, and let’s just get a basic truth out of the way. Anything pretty won’t be pretty for long if subjected to the former conditions. So in that way, Bradford Knives are actually categorically superior.

Refusal to Jump on the Folder Bandwagon

Bradford Knives may be a relatively new entrant into the market for high-quality knives, but there is one thing they utterly refuse to do.

That is jump on the popularity of folders.

For a host of reasons, folding tactical knives have surged in popularity over, say, the last 30 years. This goes beyond the ascendancy of Spyderco and Benchmade, and encapsulates other brands like Kizer, CRJB, Artisan Cutlery, CIVIVI, WE Knife Company, and countless others.

Hingeing on consumers’ collective demands for convenience and discretion, these brands have flooded the market with folders ranging in size, function and price, and the market is now awash.

We’re at the point where most people that carry everyday probably carry a folder.

And, not that there’s anything wrong with that (a folder can offer a lot of value if selected wisely) but there is also something to be said for sticking to the proverbial guns and producing fixed blades.

Which is precisely what Bradford does.

Serious Steels

Lastly, and perhaps the best reason to be interested in Bradford Knives, has to be what steels the company uses in its production of high-end fixed blades.

Here are just a few of the alloys you’ll encounter in a catalog that contains Bradford Knives: N690, Elmax, MagnaCut, M390, and CPM-3V, to name just a few.

This is not a selection of knives in which you will find budget steels like 420HC or 8Cr13MoV. Not that there’s anything wrong with them, but they are not as wear resistant, don’t offer the same carbide distribution (and therefore fall short on edge retention) and generally just aren’t as tough as the super steels enumerated.

The point is, Bradford spares no expense in its unflinching, unapologetic pursuit of quality, and that is quite evident in the steels selected for the production of its blade blanks.

Simply put, these steels are chemically stable, extremely hard and strong, wear and corrosion resistant, and easy to maintain. They’re all you could want from a knife steel and perhaps several things you didn’t know you’d want.

Interested in Bradford Knives?

Want to explore more about Bradford Knives? Check out what’s in stock at White Mountain Knives. They carry a select variety of knives from Bradford’s collection, along with models from other top brands in the industry (including those mentioned earlier in this post, along with countless others). Visit their website today and get in touch with them at WhiteMountainKnives@gmail.com if you have any questions.

For more information about Zero Tolerance Pocket Knife and Kershaw Pocket Knife please visit:- White Mountain Knives, LLC